Blog

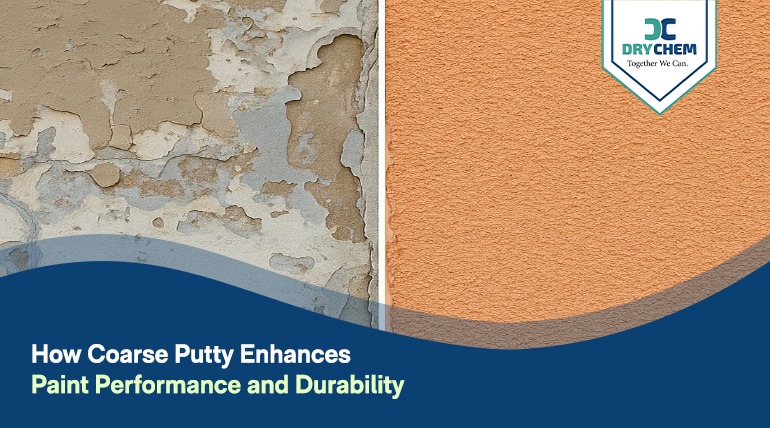

How Coarse Putty Enhances Paint Performance and Durability

When it comes to achieving long-lasting and flawless wall finishes, the secret lies beneath the surface. One of the most essential yet often ignored steps is applying coarse putty—a specially formulated base layer that prepares your wall for the final paint. Whether you are working on new construction or renovation, using white cement-based coarse putty can significantly enhance paint performance and overall durability.

In this blog, we explore how coarse putty improves surface preparation, reduces paint failure, and ensures long-term protection for your walls.

What Is Coarse Putty?

Coarse Putty is wall putty specially developed as a base coat to cover unevenness in plastered surfaces to make the walls/ceilings ready for final application. As it is white, it can be treated as a base coat for putty. It contains the finest quality mineral, white cement, dolomite and polymers. It is white cement-based wall putty to be used on concrete/mortar surface walls and ceilings. Known for its durability, strong adhesion and UV resistance, coarse putty is ideal for concrete walls, sand-cement plaster, plaster, and even asbestos sheets.

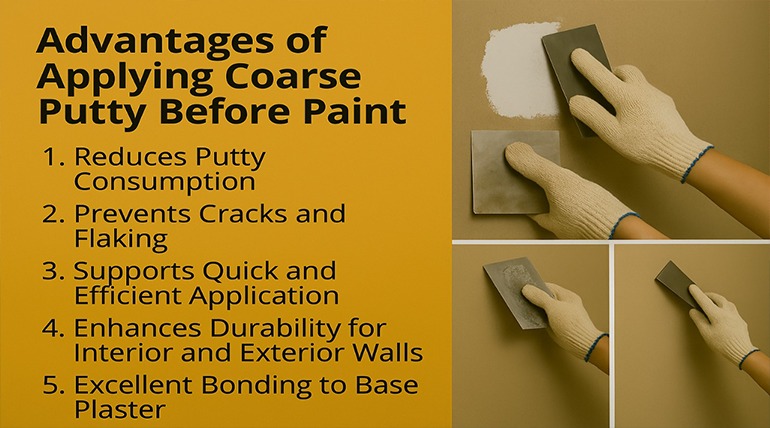

Top 6 Benefits of Coarse Putty

1. Reduces Putty Consumption

By creating an even base, coarse putty minimizes the number of coats needed for fine putty and paint. This results in reduced material usage, saving both time and costs.

2. Prevents Cracks and Flaking

Its compressive strength > 6.0 MPa and flexural strength > 1.2 MPa help resist minor wall movements, reducing the chances of cracks and paint flaking—especially in high-humidity or weather-exposed areas.

3. Supports Quick and Efficient Application

Coarse putty is fast-drying, typically ready for the next coat within 3–4 hours. It is easy to mix and apply with a putty blade, making it a convenient choice for professional applicators and contractors.

4. Enhances Durability for Interior and Exterior Walls

DryChem Coarse Putty is engineered for both indoor and outdoor surfaces, ensuring consistent performance under varying climatic conditions, including UV exposure and moisture.

5. Excellent Bonding to Base Plaster

Thanks to its superior formulation, coarse putty forms a strong mechanical bond with the substrate, reducing the risk of peeling or detachment over time.

6. UV Resistance for Longer Surface Life

It shields surfaces from UV damage, preserving the underlying layer and ensuring lasting finish integrity, especially in exposed exteriors.

Why Use Coarse Putty Before Fine Wall Putty?

Coarse putty acts as a primary levelling layer—addressing rough surfaces, filling deep pores, and preparing walls for smooth finishing. Skipping this step often leads to visible surface defects, poor paint adhesion, and reduced paint life. For optimal results, coarse putty should always be followed by fine wall putty before the final coat of paint.

Where Can You Use Coarse Putty?

- Concrete and cement plaster walls

- Ceilings (interior/exterior)

- Gypsum plaster

- Asbestos and precast surfaces

- Residential and commercial buildings

Application Guide – HomeSure Coarse Putty

Recommended Substrates

- Internal & external concrete or mortar walls

- Sand-cement plaster, asbestos sheets, Mivan plaster, etc.

- Apply before wall putty for optimal finish

Surface Preparation

- Remove loose particles, dust, grease, or any foreign matter using a wire brush, sandpaper, or chipping tools.

- For uneven or damaged surfaces, remove defective plaster and re-plaster using Ready-Mix Plaster to achieve a smooth, even base.

Mixing Instructions

- Add 1 kg of Coarse Putty to 250–300 ml of clean water in a bucket.

(Always add putty into water, not the other way around.) - Mix for 3–5 minutes using a mechanical stirrer or by hand to form a smooth, lump-free paste.

- Let the mixture rest for 10 minutes for additives to activate.

- Re-stir for 2 minutes before use.

Application Process

- Pre-wet the surface lightly and allow excess water to drain.

- Using a putty blade or patra, apply the first coat (2–3 mm) to level all undulations.

- Let it dry for 3–4 hours.

- If required, apply a second coat (1–2 mm) after complete drying.

- Once dry, proceed with the application of fine wall putty as the top layer.

Coverage

- Approx. 2–3 sq. ft./kg at 2–3 mm thickness on plain surfaces

(Coverage may vary depending on substrate conditions and layer thickness.)

Precautions

- Do not exceed the recommended water ratio.

- Maximum thickness per application should not exceed 4–5 mm.

- While non-toxic, it is advisable to wear protective gear (gloves, goggles, mask) during mixing and application.

Storage Instructions

- Store in a cool, dry place, away from direct sunlight and moisture.

- Keep bags sealed properly when not in use.

Application Tips

- Mix 1 kg of putty with 250–300 ml of clean water.

- Dampen the surface to be plastered with clean water. Allow excess water to drain off.

- Apply the first coat (2–3 mm thick) with a putty blade.

- Let it dry for 3–4 hours before the second coat (1–2 mm).

- Always follow with fine wall putty before painting.

Final Word

Investing in coarse putty before painting is not just about smoother walls—it’s about making your paint last longer, perform better, and look stunning for years to come. DryChem’s Coarse Putty is a reliable, high-performance solution tested as per IS-4031 and EN-1015 standards, delivering superior strength, durability, and coverage.

Upgrade your surface prep. Choose DryChem Coarse Putty for a professional finish that lasts.

Looking for a Toll Manufacturing Partner?

At DryChem, we don’t just deliver high-performance construction materials—we also offer end-to-end toll manufacturing services backed by BIS-standard plants, NABL-accredited labs, and a commitment to quality, consistency, and confidentiality.

Let’s build something extraordinary together.

To contact us, at